By using our website, you agree that we make use of cookies to enhance your browsing experience with Gehring.

You are using a very outdated browser. To make full use of our website, we recommend that you update your browser to the newest version.

Technologies

As the technology leader in honing processes, we are always one step ahead.

Our core business culture is to stay technologically one step ahead. We meet our customers' demand with trendsetting techniques, versatile process solutions and the developments of new ideas.

Following are several examples of the technologies developed by us.

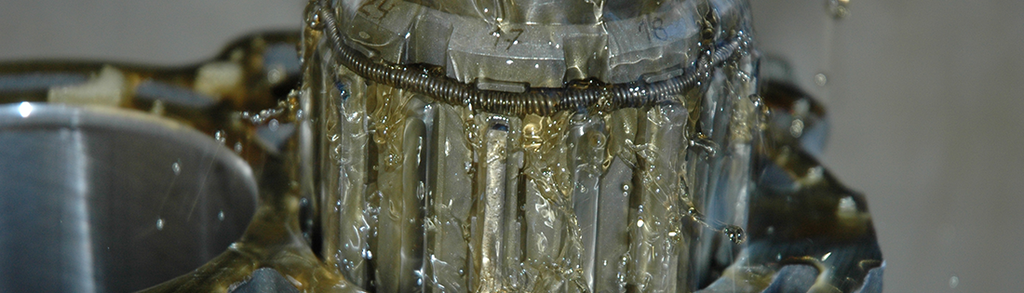

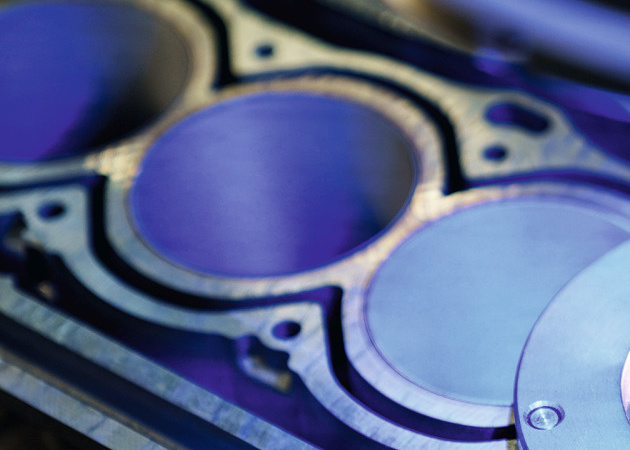

Honing how it works

The honing process as machining process produces final functional surfaces of bores of any type.

Technologie - Honen kurz erklärt - Quicklink - Triple #1: Left - en-WW

Position honing

The Position honing shortens the process chain with unchanged quality end of the cylinder bore.

Technologien - Positionshonen - Quicklink - Triple #1: Center - en-WW

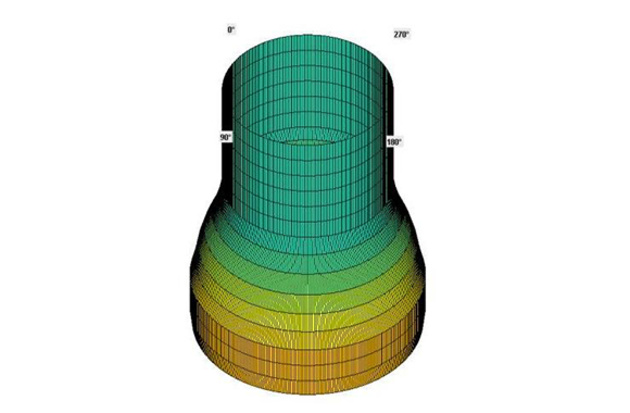

Form honing

Form honing is a process which creates non cylindrical bore geometries in cylinder liners.

Technologien - Formhonen - Quicklink - Triple #1: Right - en-WW

Sigmahoning

The high component stress requires an increase in quality and new parameters such as residual compressive stresses.

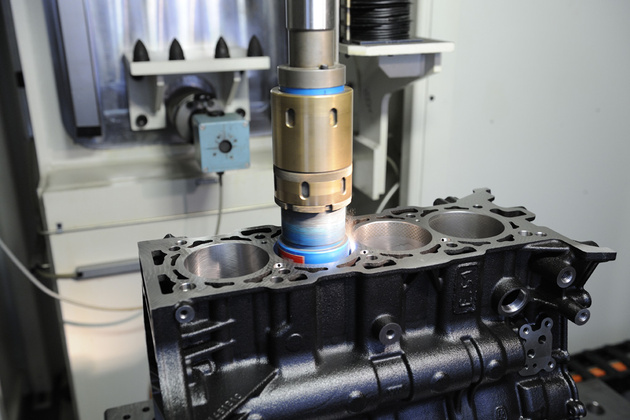

Laser-Honing

The combination of laser structuring and honing of cylinder bore surfaces is known as laser honing.

Technologien - Laser-Honen - Quicklink - Triple #2: Center - en-WW

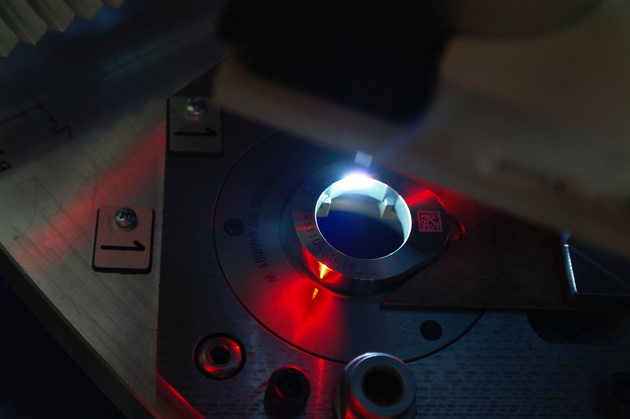

Laser structuring

This produces raised micro profiles, which achieve the highest possible static friction to the counter body.

Technologien - Laserstrukturieren - Quicklink - Triple #2: Right - en-WW

Laser roughening

In laser roughening, increasing the efficiency of the internal combustion engine is the overarching goal.

Quicklink_Laser roughening

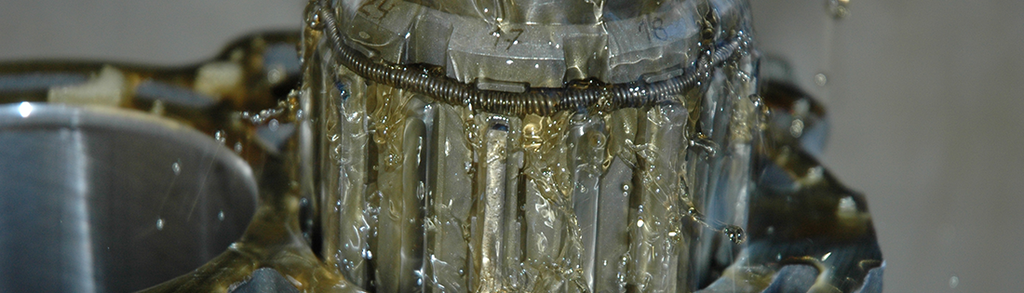

Nano honing

The combination of laser roughening, thermal spray coating and honing make nano honing the process technology of the future in regard to cylinder bores.

Technologien - Nanohonen - Quicklink - Triple #2: Left - en-WW