International

- International

- EN

- DE

- USA

- EN

- China

- 中国

- EN

You are using a very outdated browser. To make full use of our website, we recommend that you update your browser to the newest version.

Ostfildern, June 4, 2020: By start of June 2020, the Gehring Group has completed the integration of its production technology portfolio for hairpin stators within its e-motive business unit. The services and products will be offered worldwide under the Gehring brand in the future. With this step, the machine manufacturer completes the integration two years after the acquisition of the copperING group and offers its entire portfolio under the Gehring brand, from honing technology, laser technology, e-mobility to digital solutions. The locations in Wernigerode and Nuvolera, Italy will operate under Gehring Prozesstechnik GmbH and Gehring S.r.l in the future.

The technology specialist for electric drives copperING has been part of the Gehring Group since 2018. Since then, technologies and systems for the industrialization of e-mobility have been developed together with Gehring as an expert for conventional powertrain production systems.

The Italian location in Nuvolera has the experience and products related to electric motors and technologies for the production of pins for hairpin stators. The German location in Wernigerode functions as a technology center for impregnation technology. Together with Gehring's expertise in system integration and supplemented by other self-developed technology, Gehring is able to serve the global markets as a turnkey provider for stator production. “Our customers want to receive the production technology for stators from a single source - this applies to the technology in the individual process steps as well as the overall system. This way, we can meet the high demands on productivity, quality and the pace of development. Our offer is characterized by this universal claim - which is now also reflected in a uniform brand”, explains Dr. Sebastian Schöning, CEO of the Gehring Group.

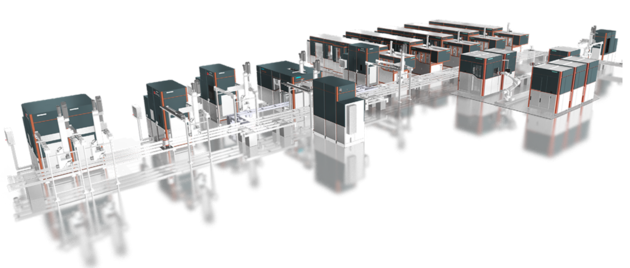

The Gehring e-motive business unit specializes in development of electric motors and sample production, as well as the design and supply of machines and production systems. This includes all aspects of prototyping, technology development and quality assurance. These capacities are combined to deliver tailored machines and production lines in turnkey projects. The technologies covered comprise pin production, slot insulation, pin assembly and widening, twisting, welding as well as impregnation, gel coating and powder coating.

The entry into e-mobile production technology and the integration of the copperING group is based on the Gehring Group's strategy for efficiency and technology openness in the automotive powertrain. In addition to emission reduction in combustion engines through the development of advanced honing, laser and coating technologies, the e-motive area enables the industrialization of e-mobility. Automobile manufacturers get their production technology from the Gehring Group's integrated, global production network.

Dr. Sebastian Schöning, CEO of the Gehring Group

Gehring stator impregnation machine in Wernigerode

Turnkey-System for volume production of stators. Gehring offers all technologies, machines and system integration from a single source.

About the Gehring Group:

The Gehring Group offers innovative production solutions for highly efficient conventional and electrified power trains. In the field of fine machining, the company has been shaping the development of honing technology for more than 90 years and provides the automotive industry with the processes of laser roughening, coating and honing answers to the current challenges around the combustion engine. The production technology for e-mobility expands the group's portfolio and sets new standards in the flexible series production of electric motors. www.gehring-group.com

Press contact

Joachim Jäckl

Gehringstraße 28

73760 Ostfildern

tel. 0711/3405-311

Categories

Tags