Laser roughening

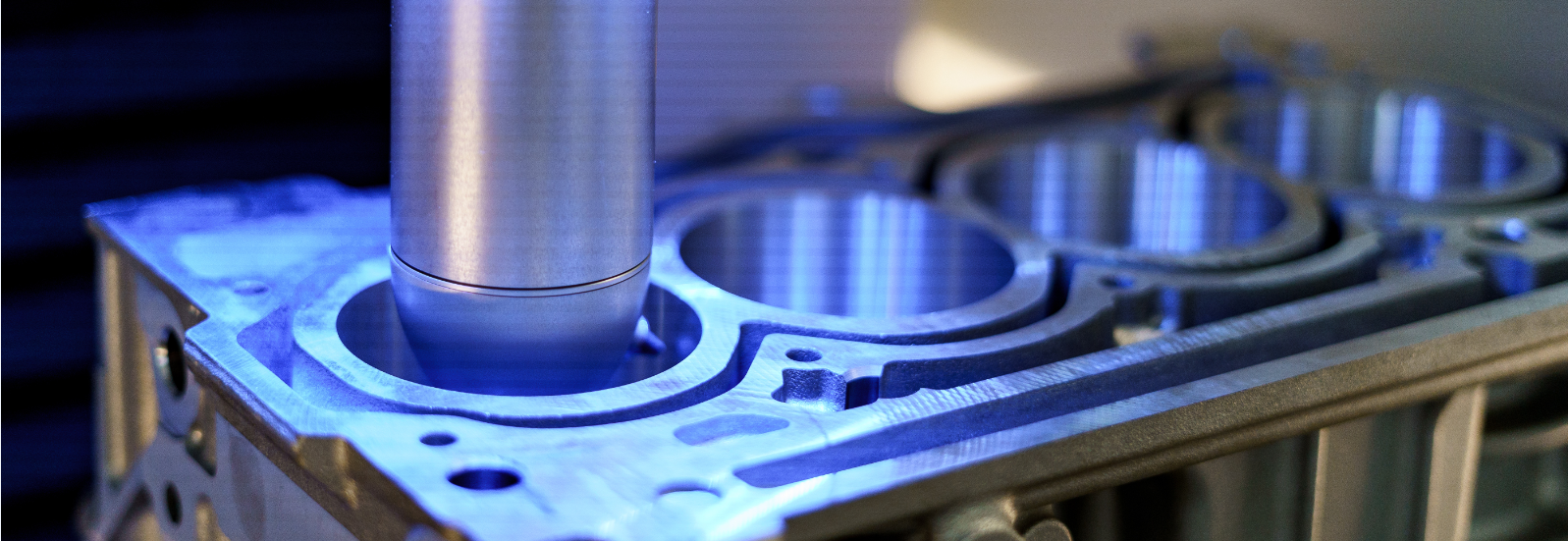

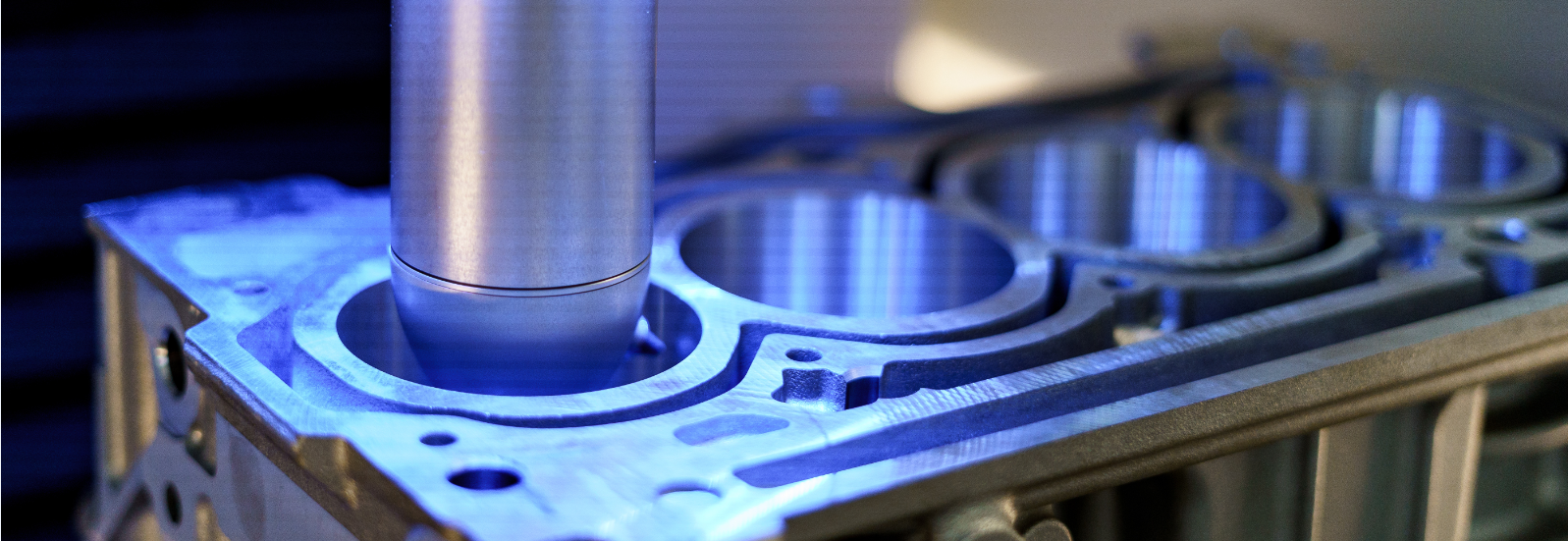

Thermal coating of cylinder bores is a highly sought-after technology, with increasing the efficiency of the combustion engine being the overriding objective.

You are using a very outdated browser. To make full use of our website, we recommend that you update your browser to the newest version.

Thermal coating of cylinder bores is a highly sought-after technology, with increasing the efficiency of the combustion engine being the overriding objective.

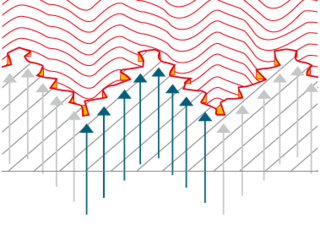

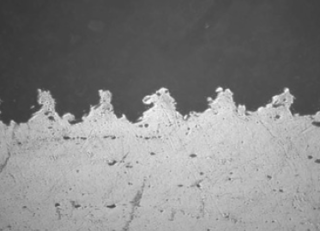

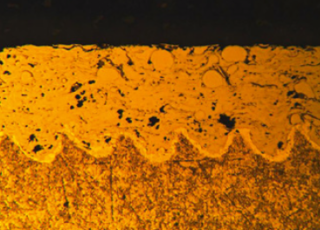

In order to produce a reliable bond between the layer and substrate, a high-performance roughening process is required which ensures functionality in all aspects. The positive interlocking connection produced by undercuts and complete filling of the profile roughness with microscopically evenly sprayed material are the essential requirements for layer adhesion.

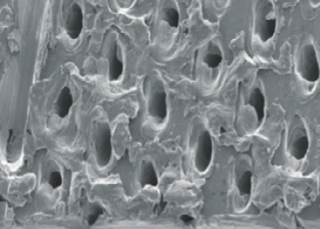

The micro positive interlocking connection across the entire surface enables high adhesive strength to be achieved. This is particularly significant for the motor function of the coating and makes the layer sufficiently durable in all directions. Another aim is a flexible design for the profile roughness. Blast parameters and process kinematics allow for both spiral profile grooves and enclosed cavities. The operating costs are relatively low because no mechanical machining is performed, which is associated with high tool costs. Laser roughening also results in considerable savings on the coating material, as high adhesive strength can be achieved even with low roughness.

When the energy-rich beam of light hits the material, energy is absorbed locally and converted into heat. Provided appropriate parameters have been selected, this results in the formation of the profile roughness best suited to the function – in the case of both aluminum and cast iron. The beam of light performs an overlapped rotary and feed movement so that the entire bore is machined in compliance with the cycle time.

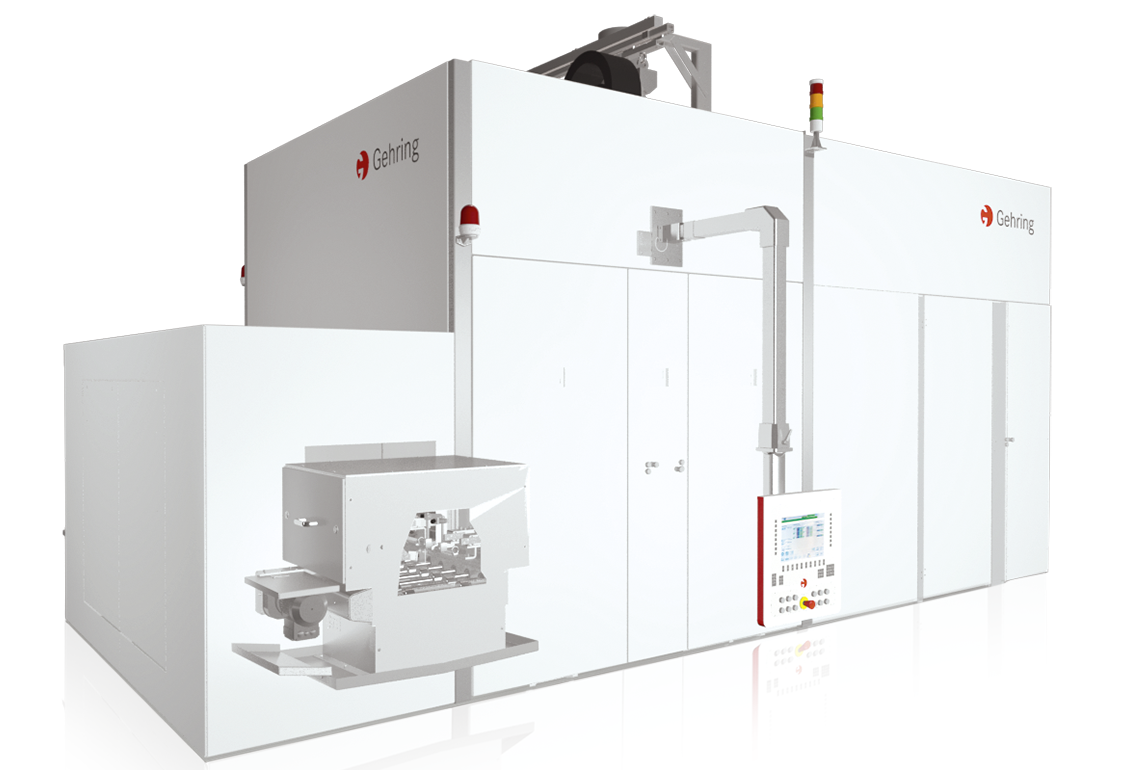

The laser roughening process is controlled by the innovative rotating optical system. Thanks to the compact design of the Gehring machines, two identical cylinder bores can be machined at the same time. The hollow-shaft motor and stationary submersible optical system enable operation with virtually no vibrations. Using high-quality materials guarantees a long service life for the optical components. An industrial camera is used to monitor the process, especially during the setup stage. The peripheral equipment for the fully automatic roughening module with optimized footprint consists of an extraction system and coolant device for the beam source and rotating optical system.

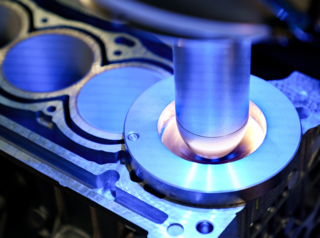

Rotating optical system for laser roughening

Our many years of previous experience with engines from different performance classes show that laser roughening is an innovative and economical process for modern series production. Laser roughening can be used as a pretreatment for all conventional thermal coating processes. The use of powerful beam sources makes it possible to machine aluminum alloys as well as cast iron. The special potential offered by laser roughening becomes apparent when machining two-stroke engines. In this process, the beam can come out of the bore and then re-enter the bore, where it remains, without causing a deterioration in the quality at the overflow ducts. Localized, targeted laser roughening is possible for selective coating in the piston‘s running area and also at the top deck chamfer. Gehring has extensive expertise in the entire „laser roughening, coating and honing“ process chain. Harmonized process steps result in lowfriction, wear-resistant cylinder surfaces.

Laser roughened surface profile

Thermal coating of aluminium

Individually enclosed cavities