Gehring Honing control

Developed for honing processes

Developed for honing processes

Our honing control was especially developed for honing processes and has already proven itself worldwide. Thanks to our especially developed software we meet highest process requirements and enable an optimum interaction of the individual components such as cylindromatic or the in-process gauging. The Gehring honing control allows controlled stroke speeds and reversal accuracy. The user-friendly, clear user interface of Gehring Operator Panel (GOP) simplifies the operation for the user.

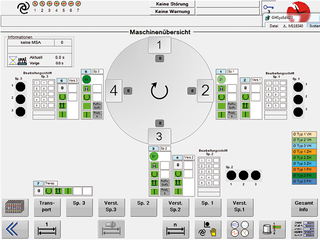

In the basic overview, transports as well as all processing and gauging stations of the machine are clearly displayed. The status of each operation is highlighted in color on each unit. So the operator can see which station is finished with which operation. If required, individual units also can be deselected and deactivated. For other actions, the operator can click on the individual stations.

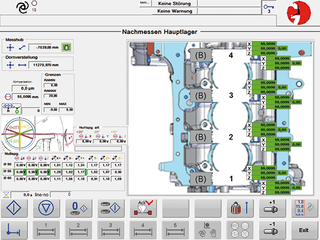

The bore diameter and conicity are determined via a pneumatic air measuring device and graphically displayed on the GOP display.

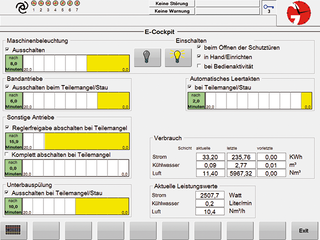

With the built-up sensors, our energy efficiency monitor displays all major energy drivers at a glance. Whether air, water or electricity consumption, you can maintain an overview of the situation.

Basic Overview

Gauging

Energy Efficiency Monitor