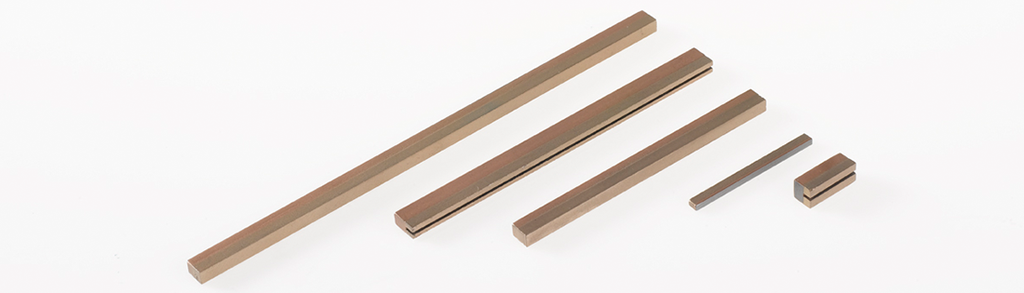

Standard Honing Stone

Gehring Diato Standard Honing Stone

Gehring Diato Standard Honing Stone

In view of our current ecological and economic challenges it becomes apparent: Honing with diamond or boron nitride cutting shoes is indispensable in modern production processes.

Numerous factors determine the honing result. The ideal composition of the honing stone and all other influencing factors to the honing process need to be coordinated in order to achieve optimal end results. High production quality, short cycle times and longevity of the tools are achieved in this way.

Defining a suitable honing stone is the task of our specialists with many years of practical experience in the most diverse of applications in the entire field of honing technology.

And not just for Gehring tools, but also tools from other manufacturers.

The abrasive layer is produced with a steel blank and the honing stone is soldered or bonded onto the stone holder of the tool.

How to order: W x H x L x Y

Example: 5.00 x 6.00 x 100.00 x 2.0

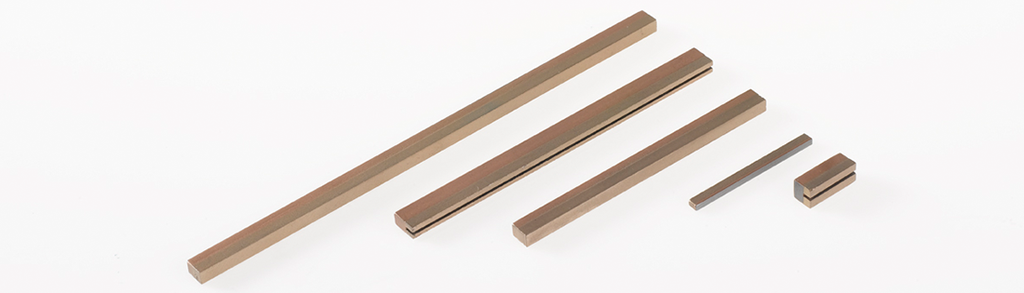

The same structure as for the standard honing stone only with longitudinally slotted abrasive.

How to order: W x H x L x Y x S

Example: 6.00 x 6.00 x 80.00 x 2.5 S 2.0

Stone with T-shaped profile with a narrow reduced section and a short wide work element in the lower area.

How to order: W x H x L x Y G x L'

Example: 3.00 x 3.00 x 45.00 x 2.0 G 7.5

Honing stone with upper and lower guide arranged symmetrically

How to order: W x H x L x Y G x L'

Example: 3.00 x 3.00 x 45.00 x 2.0 G 7.5