China

- International

- EN

- DE

- USA

- EN

- China

- 中国

- EN

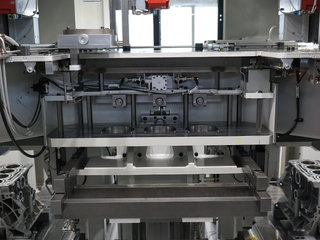

The innovative powertrainhone machine concept can be applied to all known honing processes. In addition to conventional honing, innovative processes such as position honing can also be handled. The high processing and cutting speeds, and the optimised workflows significantly boost productivity even further. Whether as stand-alone machine or as integrated production lines - the modular concept provides the highest levels of flexibility in configuring modern production solutions. Standard function modules combined with customised solutions guarantee optimal results.

Optimally equipped for the future

The compact honing unit with powerful stroke and efficient direct spindle drive stands for the highest levels of flexibility. The different sizes of the models satisfy a broad spectrum of applications, with diameters ranging from 68 to 105 mm. And the integrated electromechanical feeding unit with force control (EMZ-F) ensures that process to reproduce the desired results is capable.

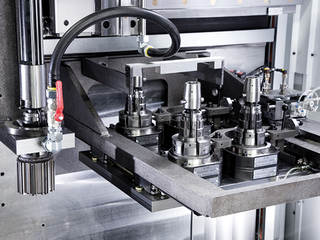

The fast and efficient tool change system, with its extremely short tool changing times, provides you with the best solution for a range of part types, as well as tool changing as a result of wear or process modifications. Typical areas of applications are all types of car crankcases - which means for example that inline blocks or V-blocks can be optimally processed, not to mention crank bores.

Tool Changers:

Sophisticated technology

Developed primarily for the honing of engine blocks with bore diameters of 68 - 105 mm, the size of the machine has been optimized. Whether as a single machine or interlinked production line - the modular concept offers maximum flexibility in the configuration of modern manufacturing solutions.

Brochure Download:

| Technical Data | PT 600 Modul |

|---|---|

| Stroke Length | 600 mm |

| Diameter | 68 - 105 mm |

| RPM, max. | 600 1/min |

| Torque, max. | 140 Nm |

| Stroke Speed, max. | 40 m/min |

| Honing Units | 2-4 |

| Loading concept | Rotary Table or Transfer |

Subject to technical changes and variations in design and configuration!

In the transfer model option virtually any number of spindle units can be installed. Depending on the required cycle time or the number of processing steps involved the transfer module offers an interesting alternative to the PT 600 module.

Brochure Download:

| Technical Data | PT 600 Transfer |

|---|---|

| Stroke Length | 600 mm |

| Diameter | 68 - 105 mm |

| RPM, max. | 600 1/min |

| Torque, max. | 140 |

| Stroke Speed, max. | 40 m/min |

Subject to technical changes and variations in design and configuration!

The PT 500K is specially designed for Position Honing and therefore the fine boring process is substituted without sacrificing surface finish quality. The higher displacement and cutting speeds as well as the optimized processes increase productivity.

| Technical Data | PT 500k |

|---|---|

| Stroke Length | 500 mm |

| Diameter | 68 - 105 mm |

| RPM, max. | 2.000 1/min |

| Torque, max. | 90 Nm |

| Stroke Speed, max. | 40 m/min |

Subject to technical changes and variations in design and configuration!

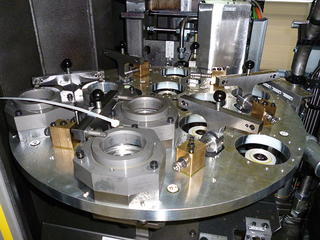

The new modular powertrainhone Z enables the full honing process in one module. Whether three- or four-cylinder, efficiency and shorter cycle times for honing are assured thanks to the three processing stations.

Brochure Download:

| Technical Data | Z 750 |

|---|---|

| Stroke Length | 750 mm |

| Diameter | 68 - 105 mm |

| RPM, max. | 450 1/min |

| Torque, max. | 190 Nm |

| Stroke Speed, max. | 40 m/min |

Subject to technical changes and variations in design and configuration!

Depending on the required lot size, cycle time or number of processing steps, the transfer module option provides an interesting alternative to the powertrainhone Z module. The spindles are optimally accessible through a direct maintenance area.

| Technical Data | Z 750 |

|---|---|

| Stroke Length | 750 mm |

| Diameter | 68 - 105 mm |

| RPM, max. | 450 1/min |

| Torque, max. | 190 Nm |

| Stroke Speed, max. | 40 m/min |

Subject to technical changes and variations in design and configuration!

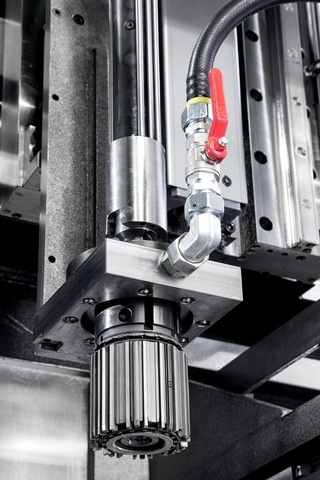

The LSR (Large Scale Reaming) honing unit of the powertrainhone series can be used as a modular machine or as an integrated solution in a transfer line. The horizontal honing unit ensures precise and effective machining of crank bores in engine blocks. Driven by a servo motor and equipped with an electro-mechanical feeding system, optimized machining results are achieved.

The machining of the crank bore improves the geometrical and positional accuracy. The used ream honing process is characterized by maintaining close tolerances and long tool life. This results in high process availability with low tooling costs. The ream honing is a contribution to the future sustainability of the combustion engine.

The LSR module can alternatively be equipped with one or two honing units and optionally supplemented by an automatic tool changer. In combination with the HSK connection, quick tool changes can be assured. Overall, this machine offers quality at the highest level.

| Technical Data | LSR 2000 |

|---|---|

| Stroke Length | 2.000 mm |

| Diameter | 45 - 90 mm |

| RPM, max. | 150 1/min |

| Rated Power | 5,5 kW |

| Stroke Speed, max. | 20 m/min |

Subject to technical changes and variations in design and configuration!

The machine is designed for bore diameters from 60 to 110 mm and can be designed as a single-spindle machine or with a powerful two-spindle variation as needed. Engine blocks of all kinds as well as liners are the main areas of application.

Brochure Download:

| Technical Data | Solo LV1 | Solo HV2 |

|---|---|---|

| Stroke Length | 600 mm | 600 mm |

| Diameter | 60 - 110 mm | 60 - 110 mm |

| RPM, max. | 450 1/min | 450 1/min |

| Torque, max. | 125 Nm | 125 Nm |

| Stroke Speed, max. | 30 m/min | 30 m/min |

Subject to technical changes and variations in design and configuration!

Precision with the Gehring Tool System

Precision and longevity are the hallmarks of our tooling systems. Our tool systems guarantee the highest levels of efficiency, optimised surfaces, and the best possible bore geometries.

Profit from the Gehring tool concept which is specially customised for each machine. More information about our PT-Series.